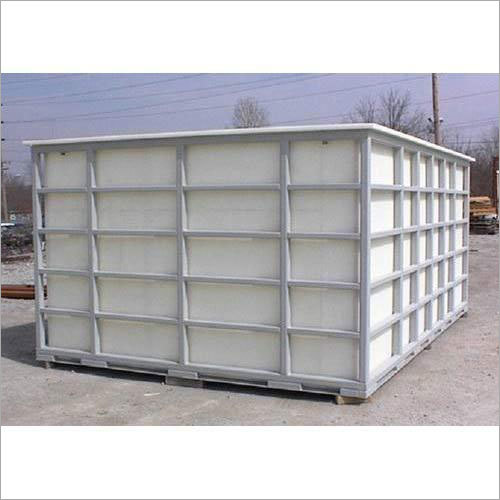

Electroplating Tank

About Electroplating Tank

Designed and fabricated for different capacities (upto 200KL), temperature and pressure conditions, these tanks offer superior life span when used for the storage of acids, alkalies and other corrosive chemicals. MOC offered are FRP (all grades of resins), PPH, PVC, PVDF, HDPE, composites (PP-FRP, PVC-FRP, PVDF-FRP, MS-FRP), SS 316 & 304. MOC selection is vigilantly done considering the nature of chemical & its temperature & pressure conditions. FRP Tanks are manufactured with Contact Moulding (Hand lay-up) method and the thermoplastic tanks are welded on European Butt welding machine as per German standards which offer a long-term welding factor of 0.8 instead of 0.6 offered by rod welded tanks. Accessories like agitators, level indicators, monkey ladders, railings and structures for conical bottoms are also manufactured by us.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Tanks Category

PPH Pickling Tank

Price 200000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : PP FRP

Usage : Chemical Water Oil

Application : Storage

Shape : Customized

Polypropylene Tank

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Polypropylene

Usage : Industrial

FRP Chemical Storage Tank

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : FRP

Usage : Industrial

Acid Storage Tank

Price 24998.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Application : Industrial

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free